**Top Features and Benefits of a Small Metal Laser Cutter**

Are you looking for a versatile and precise tool to handle your small metal projects? Look no further than the **small metal laser cutter**. This innovative device is designed to meet the needs of both hobbyists and professionals, offering unparalleled precision and efficiency in cutting and engraving various materials. Whether you’re working on custom jewelry, decorative pieces, or industrial prototypes, this machine has become a go-to solution for many crafters and manufacturers. In this article, we’ll explore the features, benefits, and applications of this incredible tool, as well as answer some common questions about its use and maintenance.

What is a Small Metal Laser Cutter?

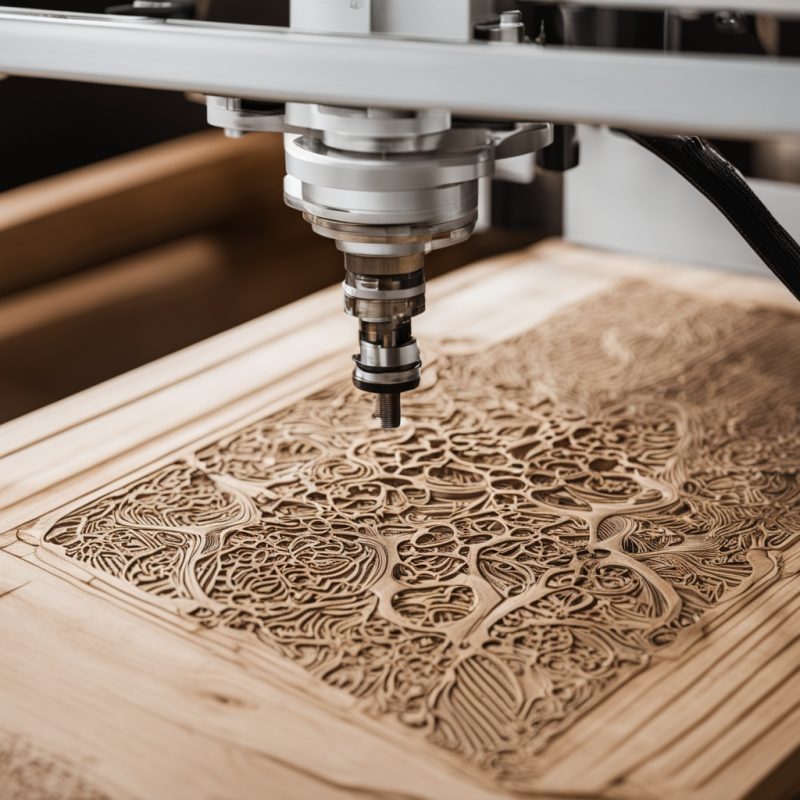

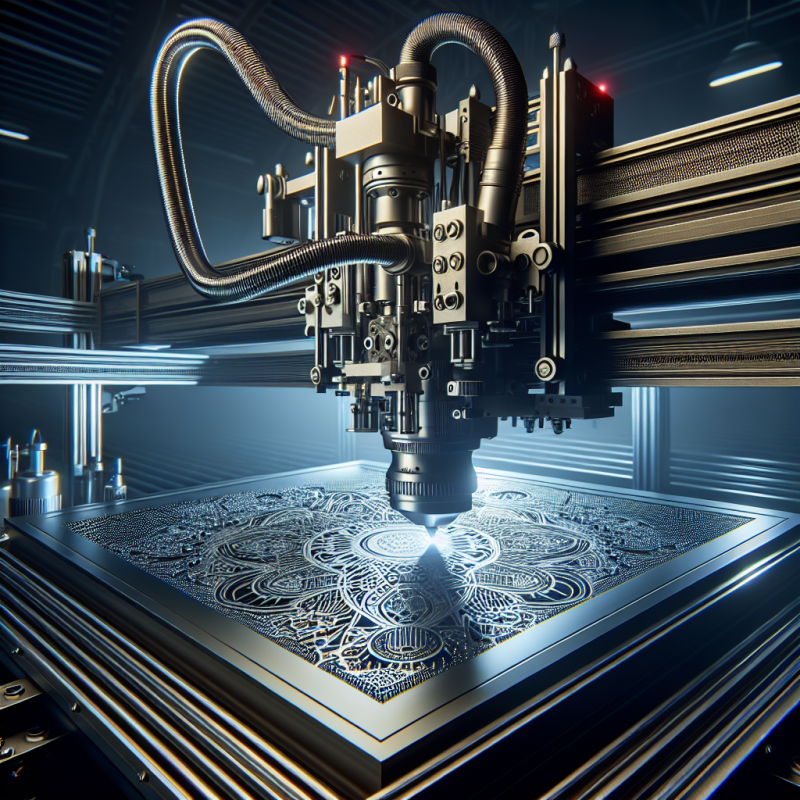

A **small metal laser cutter** is a compact yet powerful machine that uses a high-intensity laser beam to cut, engrave, or etch materials. Unlike traditional cutting tools, this device operates with exceptional precision, making it ideal for intricate designs and small-scale projects. The machine is equipped with advanced features such as CNC (Computer Numerical Control) technology, allowing users to input designs via software and achieve exact results every time.

One of the standout features of this tool is its ability to work with a variety of materials, including steel, stainless steel, aluminum, and other metals. This versatility makes it an excellent choice for artists, craftsmen, and small-scale manufacturers who need a reliable solution for their projects. The **small metal laser cutter** is also perfect for those who value space efficiency, as its compact design allows it to fit easily on most workbenches or in home workshops.

Key Features of the Small Metal Laser Cutter

The **small metal laser cutter** comes packed with features that make it a must-have tool for any craftsperson. Here are some of its key attributes:

- CNC Technology: Enables precise control over cutting patterns and designs, ensuring accuracy down to the millimeter.

- Laser Power: Delivers high-powered laser beams capable of cutting through various metals with ease.

- User-Friendly Interface: Intuitive software that allows even beginners to create and execute complex designs without prior experience.

- Compact Design: Fits seamlessly into small workspaces, making it ideal for home use or mobile applications.

- Versatility: Capable of cutting, engraving, and etching a wide range of materials, including metals, plastics, and wood.

These features not only enhance the functionality of the machine but also make it accessible to users with varying skill levels. Whether you’re a seasoned professional or just starting out, this tool offers the precision and versatility needed to bring your creative visions to life.

Benefits of Using a Small Metal Laser Cutter

Investing in a **small metal laser cutter** comes with numerous benefits that can significantly improve your workflow and project outcomes. Some of the key advantages include:

- Precision Cutting: The machine’s high-precision laser ensures clean, accurate cuts every time, minimizing waste and maximizing efficiency.

- Time Efficiency: With its advanced cutting capabilities, this tool can complete projects in a fraction of the time it would take using traditional methods.

- Versatility: Capable of handling multiple materials and project types, making it a cost-effective investment for various applications.

- Reduced Manual Labor: The CNC technology allows for automated cutting, reducing the need for manual intervention and minimizing errors.

These benefits make the **small metal laser cutter** an invaluable tool for anyone looking to streamline their production process or enhance their creative projects. Whether you’re working on a large-scale manufacturing project or a small, intricate piece of art, this machine delivers results that are second to none.

Applications of the Small Metal Laser Cutter

The **small metal laser cutter** has a wide range of applications across various industries and hobbies. Some common uses include:

- Jewelry Making: Create intricate designs for necklaces, bracelets, earrings, and other jewelry pieces with precision and ease.

- Decorative Art: Engrave or cut decorative patterns into metal sheets for home decor, wall art, or custom gifts.

- Industrial Prototyping: Develop prototypes for small metal components quickly and efficiently, reducing production time and costs.

- Promotional Items: Customize keychains, name tags, and other promotional items with laser-cut designs that stand out.

Its versatility makes it an ideal tool for both large-scale manufacturers and small-scale crafters. Whether you’re creating a one-of-a-kind piece or producing multiple identical components, the **small metal laser cutter** is up to the task.

Frequently Asked Questions About the Small Metal Laser Cutter

If you’re considering purchasing a **small metal laser cutter**, you may have several questions about its use and maintenance. Here are some common concerns addressed:

- Is it safe to use? Yes, when operated according to safety guidelines, the machine is safe for both home and professional use. Always wear protective eyewear and follow proper handling procedures.

- What materials can it cut? The machine is designed to work with various metals, including steel, stainless steel, aluminum, and more. It can also cut plastics and wood, making it highly versatile.

- How easy is it to learn? With its user-friendly interface and intuitive software, even beginners can quickly master the machine’s operation. Basic training or online tutorials are often sufficient to get started.

- Does it require special maintenance? Regular cleaning of the laser optics and periodic software updates are recommended to ensure optimal performance. Proper maintenance extends the life of the machine and maintains its precision.

By addressing these common questions, you can feel more confident in your decision to invest in a **small metal laser cutter** and make the most of its capabilities.

Maintenance Tips for Your Small Metal Laser Cutter

To ensure that your **small metal laser cutter** performs optimally for years to come, it’s essential to follow proper maintenance practices. Here are some tips to keep in mind:

- Clean Regularly: Dust and debris can accumulate on the machine’s optics and other components, affecting performance. Clean these areas regularly using a soft cloth and appropriate cleaning solutions.

- Update Software: Keep the machine’s software up to date to access the latest features and improvements.

- Check Laser Alignment: Periodically verify that the laser is properly aligned to ensure accurate cuts and engravings.

By taking these steps, you can maintain the machine’s efficiency and prolong its lifespan, ensuring that it remains a reliable tool for all your future projects.

Conclusion: Why Every Crafter Needs a Small Metal Laser Cutter

In conclusion, the **small metal laser cutter** is an indispensable tool for anyone looking to enhance their creative projects or streamline their production process. Its precision cutting capabilities, versatility, and time-saving benefits make it a worthwhile investment for both professionals and hobbyists alike.

Whether you’re creating custom jewelry, decorative art, or industrial prototypes, this machine delivers exceptional results that are sure to impress. By addressing common concerns and following proper maintenance practices, you can maximize the machine’s potential and enjoy years of reliable service.

If you haven’t already invested in a **small metal laser cutter**, now is the perfect time to consider how it can elevate your work and bring your creative visions to life with unprecedented precision and efficiency.