“

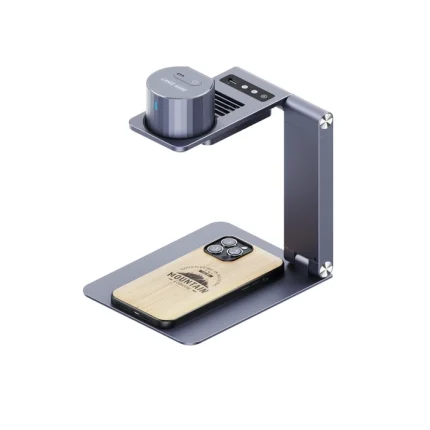

Introducing the LaserHawk LH4, a state-of-the-art laser cutting and engraving machine designed to revolutionize your creative and industrial projects. Whether you’re a hobbyist, a small business owner, or a professional manufacturer, the LaserHawk LH4 offers unparalleled precision, versatility, and efficiency.

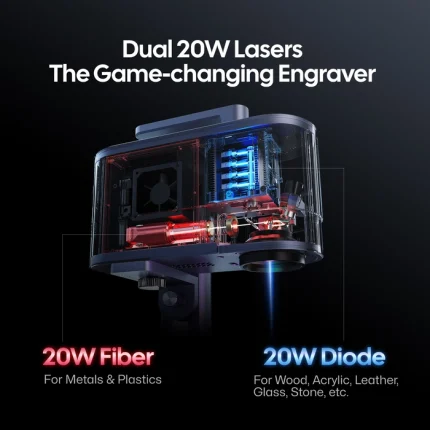

With its advanced pmag engraving ir laser technology, the LaserHawk LH4 delivers exceptional results on a wide range of materials, including wood, acrylic, leather, and even laser engraving on glass. This machine is perfect for creating intricate designs, personalized gifts, and high-quality industrial components.

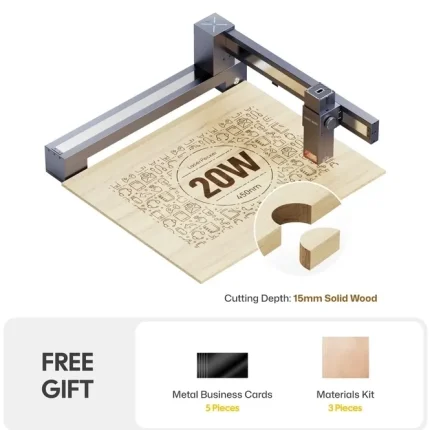

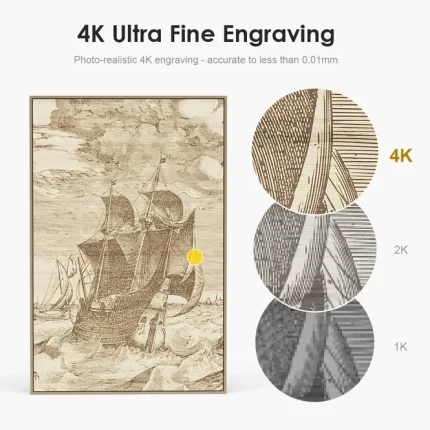

- High Precision: Achieve detailed and accurate cuts and engravings with the LaserHawk LH4’s advanced laser technology.

- Versatility: Compatible with a variety of materials, making it ideal for diverse applications.

- User-Friendly: Easy-to-use interface and software, suitable for both beginners and experts.

- Durability: Built with high-quality components to ensure long-lasting performance.

- Safety Features: Equipped with safety mechanisms to protect users and the machine during operation.

Experience the future of laser technology with the LaserHawk LH4. Whether you’re engraving intricate patterns on glass or cutting through thick materials, this machine is your ultimate tool for precision and creativity. Elevate your projects and bring your ideas to life with the LaserHawk LH4.

More you like:

Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro

Christopher Sato (verified owner) –

**Laser Engraver Experience in Product Prototyping**

**Specific Project Experience: Medical Device Prototypes**

– **Project Overview**: Utilized the laser engraver for high-precision engravings on medical devices, involving materials like stainless steel and ABS plastic.

– **Material Behavior & Results**: Stainless steel required careful power settings to achieve sharp engravings without thermal damage. ABS plastic demanded precise control to prevent warping.

– **Challenges & Solutions**: Ensuring consistent engraving depth across multiple units was challenging. This was addressed through custom software settings and regular calibration checks, ensuring uniformity and quality.

**Business/Creative Impact**

– **Workflow Improvement**: The laser engraver significantly accelerated prototyping cycles, allowing for quicker iterations and faster product development timelines compared to manual methods.

– **Customer Feedback**: Clients appreciated the precision and clarity of engravings, which were crucial for regulatory compliance. This enhanced client satisfaction and trust.

– **Return on Investment (ROI)**: Despite initial costs, the tool reduced material waste and rework, leading to long-term savings. Faster prototyping cycles also contributed to quicker time-to-market, improving competitive edge.

**Technical Performance**

– **Power & Precision**: The machine’s adjustable power settings were essential for handling both metals and plastics. High precision ensured that even delicate engravings were accurate and consistent.

– **Software Experience**: The software was user-friendly with capabilities to import complex CAD files directly, streamlining the workflow and reducing setup time.

– **Special Features**: Automatic focus adjustment proved invaluable, maintaining engraving quality across varying material thicknesses.

**Comparison & Value**

– **Previous Tools**: Replaced manual engraving, which was error-prone and time-consuming. The laser system improved efficiency and quality, reducing rework.

– **Cost-Effectiveness**: Lower maintenance costs and higher throughput compared to older machines made the investment worthwhile, with savings offsetting initial expenses over time.

– **Time Savings**: Projects that previously took days now completed in hours, freeing resources for other critical tasks and enhancing overall productivity.

This experience highlights how the laser engraver not only improved technical precision but also drove business growth by meeting stringent industry standards efficiently.

Soo Dubois –

“This laser engraver exceeds my expectations with its exceptional engraving precision and detail. The operating system is intuitive and user-friendly, making it a breeze to set up and get started. The results are clean and crisp, perfect for intricate designs. It’s a game-changer for my small business.”