Laser Engraving Metal: A Complete Guide to Precision and Customization

Laser engraving has revolutionized the way we create intricate designs and patterns on metal surfaces. With advancements in technology, *laser engravers for metal* have become more accessible, allowing both professionals and hobbyists to achieve precision and creativity. Whether you’re working on jewelry, signage, or industrial parts, laser engraving offers a versatile solution that combines speed, accuracy, and durability. In this article, we’ll explore everything you need to know about *laser engravers for metal*, including their benefits, applications, and how they work.

What Are Laser Engravers for Metal?

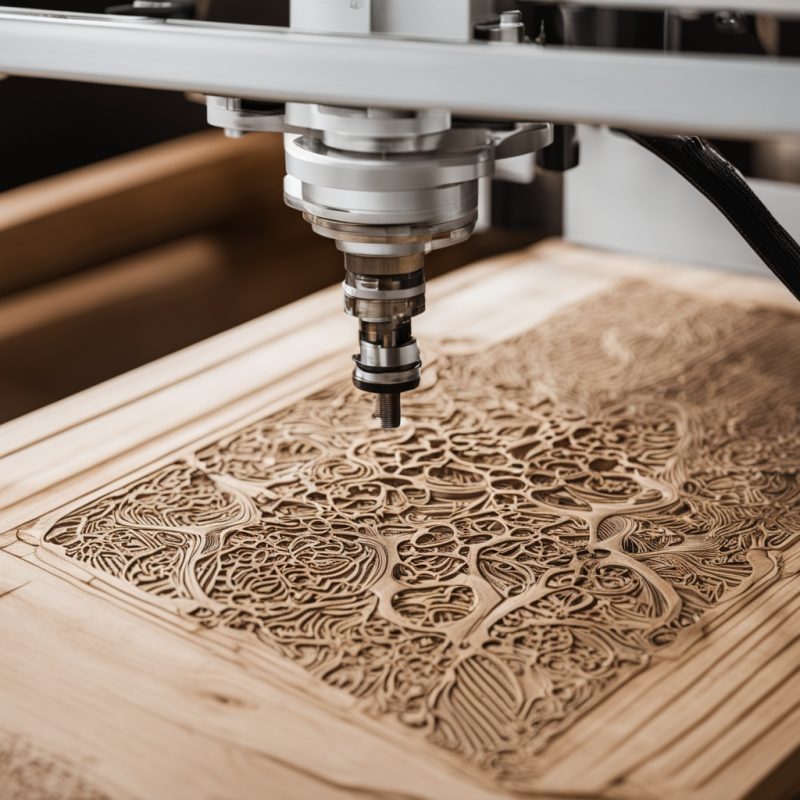

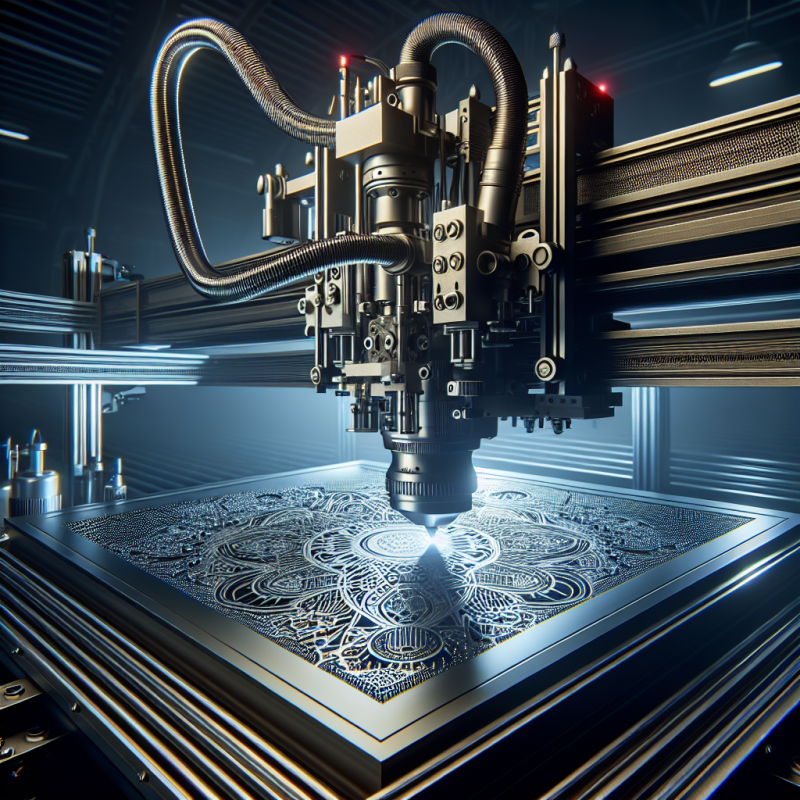

Laser engravers are machines that use high-powered lasers to designs, patterns, or text onto various materials, including metal. Unlike traditional methods like acid etching or mechanical engraving, laser engraving is non-contact and highly precise. The process involves directing a focused laser beam at the metal surface, which vaporizes or melts the material to create permanent markings. This method is ideal for metals like steel, stainless steel, aluminum, titanium, and brass, making it a popular choice in industries ranging from manufacturing to art.

How does laser engraving differ from other methods? Laser engraving offers several advantages over traditional techniques:

- No physical contact with the material, reducing wear and tear

- High precision and detail, suitable for complex designs

- Faster processing times compared to manual methods

- Ease of use with computer-controlled systems

- Durable and permanent markings that resist fading or wear

If you’re looking for a reliable tool to create custom metal engravings, consider exploring the *laser engravers for metal* available at this link.

Benefits of Using Laser Engravers for Metal

The use of laser engravers in metalworking offers numerous benefits, making them a preferred choice for both small-scale and large-scale projects:

- Precision and Detail: Laser engraving allows for intricate designs with unmatched accuracy. Even the smallest details can be reproduced faithfully on metal surfaces.

- Durability: The markings created by laser engravers are permanent and resistant to wear, making them ideal for long-lasting applications like identification tags or decorative items.

- Speed and Efficiency: Compared to manual engraving methods, laser engravers significantly reduce processing time, especially when working on large batches or repetitive designs.

- Versatility: Laser engravers can handle a wide range of metals and thicknesses, making them suitable for various industries such as jewelry-making, automotive manufacturing, and electronics.

- Ease of Use: Modern laser engravers are equipped with user-friendly software that allows even beginners to create professional-grade engravings with ease.

*Why should you invest in a laser engraver for metal?* The answer lies in its ability to transform your ideas into reality with precision and efficiency. Whether you’re running a small workshop or experimenting with DIY projects, a laser engraver can be a game-changer.

Applications of Laser Engravers for Metal

The versatility of laser engraving makes it suitable for a wide array of applications:

- Jewelry Making: Creating personalized engravings on rings, bracelets, necklaces, and other accessories.

- Signage and Plaques: Producing durable and elegant signs, plaques, and awards with custom designs.

- Industrial Marking: Engraving serial numbers, barcodes, or logos on machinery parts for identification and traceability.

- Automotive Industry: Customizing vehicle parts, engine components, and decorative elements with intricate patterns.

- Art and Design: Creating unique metal art pieces, sculptures, and decorative items with high precision.

Laser engraving is not just a tool for industrial use; it’s also a creative medium that allows artists to push the boundaries of their imagination. With the right equipment, you can bring your artistic vision to life on metal surfaces.

Choosing the Right Laser Engraver for Metal

If you’re planning to invest in a laser engraver for metal, it’s essential to consider several factors to ensure you choose the best option for your needs:

- Type of Laser: The most common types are CO2 and fiber lasers. Fiber lasers are generally more powerful and suitable for thicker metals, while CO2 lasers are ideal for thin sheets.

- Power Output: Higher power output allows for faster engraving and deeper cuts, making it suitable for industrial applications.

- Software Compatibility: Look for machines with user-friendly software that supports popular design formats like SVG, DXF, and JPG.

- Dust Extraction System: Ensures clean engraving and prolongs the lifespan of your machine.

- Budget: Determine your budget and compare features to find a balance between cost and performance.

*What are the top brands to consider?* Well-known brands like Epilog, Trotec, and Laserax offer high-quality laser engravers for metal. However, you can also explore affordable options from trusted retailers at this link.

Tips for Using Laser Engravers on Metal

To get the best results from your laser engraver, follow these tips:

- Prepare Your Design Properly: Ensure your design is optimized for engraving by adjusting line widths and spacing. Use high-resolution images to avoid pixelation.

- Test on Scrap Metal First: Experiment with different settings on scrap metal before working on your final project to ensure the best results.

- Maintain Proper Focus: Ensure the laser beam is properly focused to achieve clean and precise engravings.

- Use Protective Gear: Always wear safety goggles and gloves when operating a laser engraver.

- Keep the Work Area Clean: Regularly clean dust and debris from the machine to maintain performance and longevity.

Maintenance and Safety Tips for Laser Engravers

To ensure your laser engraver operates efficiently and safely, follow these maintenance and safety guidelines:

- Clean Regularly: Dust and debris can accumulate inside the machine, affecting performance. Use compressed air or a soft brush to clean the interior.

- Check Laser Alignment: Misaligned lasers can lead to poor engraving quality. Periodically check and adjust the alignment if necessary.

- Replace Consumables: Replace the dust filter, laser tube, or other components as recommended by the manufacturer.

- Avoid Overheating: Allow the machine to cool down between extended use periods to prevent overheating and damage.

- Store Properly: When not in use, store the laser engraver in a dry and dust-free environment.

By taking good care of your laser engraver, you can extend its lifespan and maintain optimal performance for years to come.

Frequently Asked Questions About Laser Engravers for Metal

1. Can I engrave on any type of metal?

While most metals can be engraved with a laser, harder materials like stainless steel and titanium may require higher-powered lasers.

2. How deep can a laser engraver cut into metal?

The depth depends on the laser’s power and settings. Higher power allows for deeper cuts, but it’s important to test on scrap material first.

3. Is laser engraving permanent?

Yes, laser engravings are durable and resistant to wear, making them ideal for long-lasting markings.

4. Can I change the font or design easily?

Absolutely! Most laser engravers support various fonts and design formats, allowing you to customize your projects effortlessly.

5. Is it safe to use a laser engraver at home?

Yes, as long as you follow safety guidelines like wearing protective gear and ensuring proper ventilation in the workspace.

Conclusion

Laser engraving on metal opens up endless possibilities for creativity and precision. Whether you’re an artist, hobbyist, or professional, a laser engraver can be a valuable tool in your workshop. With the right equipment, technique, and maintenance, you can create stunning engravings that stand the test of time.

If you’re ready to take the plunge into the world of laser engraving, consider exploring the options available at . They offer a wide range of high-quality laser engravers that cater to various needs and budgets. Happy engraving!

**Note:** Always prioritize safety when operating laser equipment, and ensure you’re using it in compliance with local regulations.

Laser engraving on metal is a versatile and precise method for creating durable markings and intricate designs. Here’s a concise guide to using laser engravers on metal:

### Key Points:

1. **Types of Lasers**:

– **CO2 Lasers**: Suitable for thin sheets and non-metallic materials.

– **Fiber Lasers**: Ideal for thicker metals due to higher power output.

2. **Applications**:

– Jewelry making, signage, industrial marking, automotive detailing, and artistic designs.

3. **Choosing the Right Engraver**:

– Consider factors like laser type, power output, software compatibility, dust extraction, and budget.

4. **Tips for Best Results**:

– Test on scrap metal first.

– Maintain proper focus and use protective gear.

– Keep the work area clean to avoid contamination.

5. **Maintenance & Safety**:

– Regularly clean the machine and check laser alignment.

– Replace consumables as needed and avoid overheating.

– Store properly in a dry, dust-free environment.

6. **FAQs**:

– Most metals can be engraved with appropriate power settings.

– Laser engravings are permanent and highly durable.

– Customization is straightforward with supported fonts and design formats.

– Home use is safe when following safety guidelines.

### Conclusion:

Laser engraving offers endless creative possibilities. For those ready to explore, consider options at [Laser Marking Machine](https://lasermarkingmachine.cc/). Always prioritize safety and compliance with regulations.

**Note:** Ensure safe operation and adherence to local regulations when using laser equipment.